Quality Control

Ensuring the utmost in quality control, our commitment to excellence is reflected in every aspect of our electric heaters. Rigorous tests, including noise tests, temperature tests, and various other meticulous tests, are conducted to guarantee superior performance.

Incoming Material Inspection

Ensuring the quality and conformity of raw materials before production.

Initial Product Quality Inspection

Conducting preliminary quality checks on products during the assembly process to ensure they meet standards.

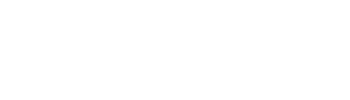

Noise Test

Ensuring a quiet and serene heating experience, our heaters undergo thorough noise testing.

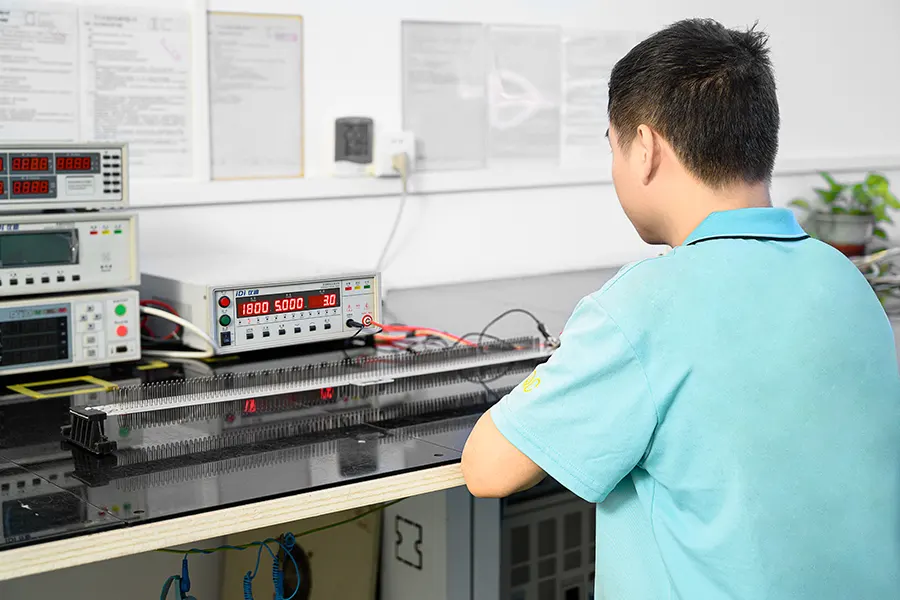

Temperature Rise Test

Guaranteeing both efficiency and safety, our heaters are subjected to a temperature rise test.

Extreme Temperature Test

Confronting the challenges of harsh climates, our heaters excel in extreme temperature testing. Crafted to endure, these heaters reliably provide warmth, regardless of the demanding environmental conditions.

Finished Product Life Test

Undergoing an intensive 3000-hour uninterrupted aging test, our heaters are meticulously examined for durability and performance. This ensures that our products can withstand the rigors of continuous use.

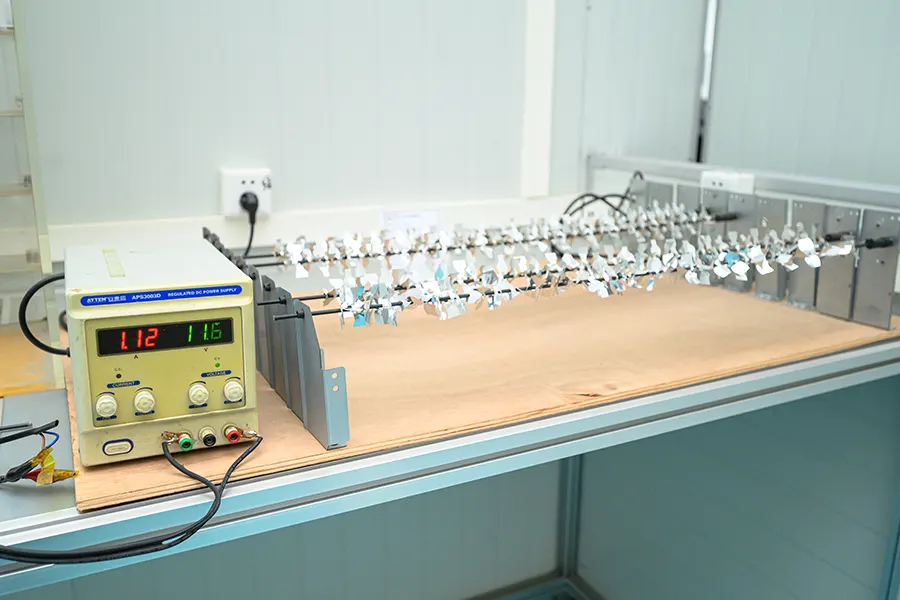

Component Life Test

Each component of electric heaters undergoes a life test. This meticulous examination guarantees that every element contributes to the overall durability and dependability of our heating solutions.

Material (Glow-wire) Test

Prioritizing safety in every detail, our heaters undergo a glow-wire test. This ensures that the materials used meet stringent safety standards, emphasizing our commitment to your safety and well-being.

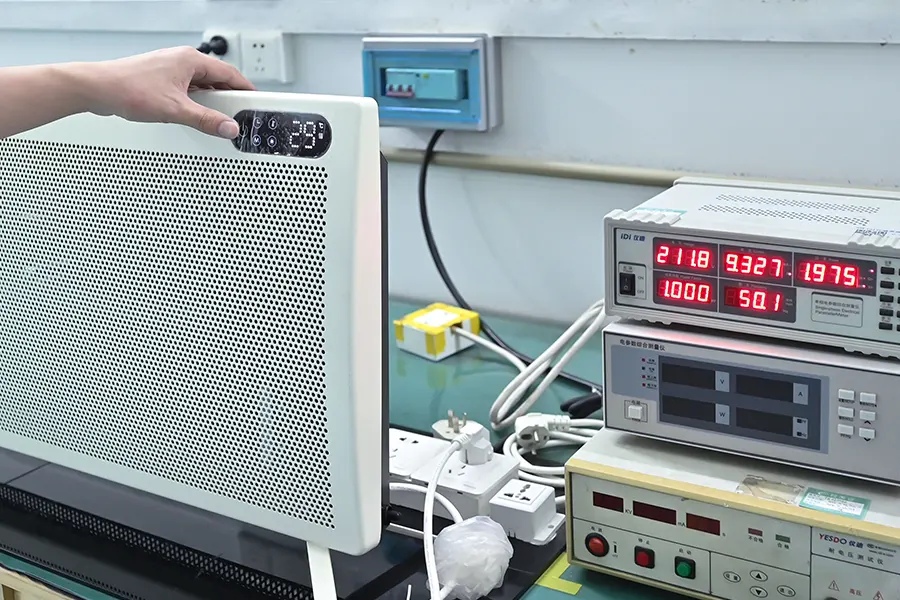

Function Test

Validating seamless functionality, our heaters undergo a meticulous function test to ensure you receive flawless units.

Packaging Vibration Test

With a focus on protection, our heaters are meticulously packaged, passing through a vibration test. This ensures they reach you in optimal condition, ready to provide consistent warmth with utmost care.