When it comes to home comfort or industrial heating, few appliances are as essential—and widely used—as the elektrische Heizung. Whether you’re sourcing products as a distributor or weighing the pros and cons of a gas heater or electric heater, understanding how electric heaters are made can give you the edge in selecting the right supplier or partner factory.

In diesem Ratgeber, we’ll walk through the entire production process of electric heaters, from raw materials to final assembly. You’ll also gain insights into maintenance tips, what makes a reliable air cooler manufacturer, and how electric heater technology continues to evolve.

Material Selection: The Foundation of Quality

Choosing the Right Heating Elements

Nickel-chromium (NiCr) alloys are commonly used for the core heating element because of their excellent electrical resistance and heat tolerance.

Some factories may opt for PTC (positive temperature coefficient) ceramic materials, known for safer, self-regulating heat output.

The material must be corrosion-resistant and able to withstand prolonged high temperatures.

Insulating Components

Mica sheets or ceramic insulators are used to separate the heating wire from the metal casing, ensuring safe electrical insulation.

High-temperature insulation is key to product longevity and user safety.

Outer Casing Materials

Typically made of stainless steel or powder-coated aluminum, offering both durability and heat conduction.

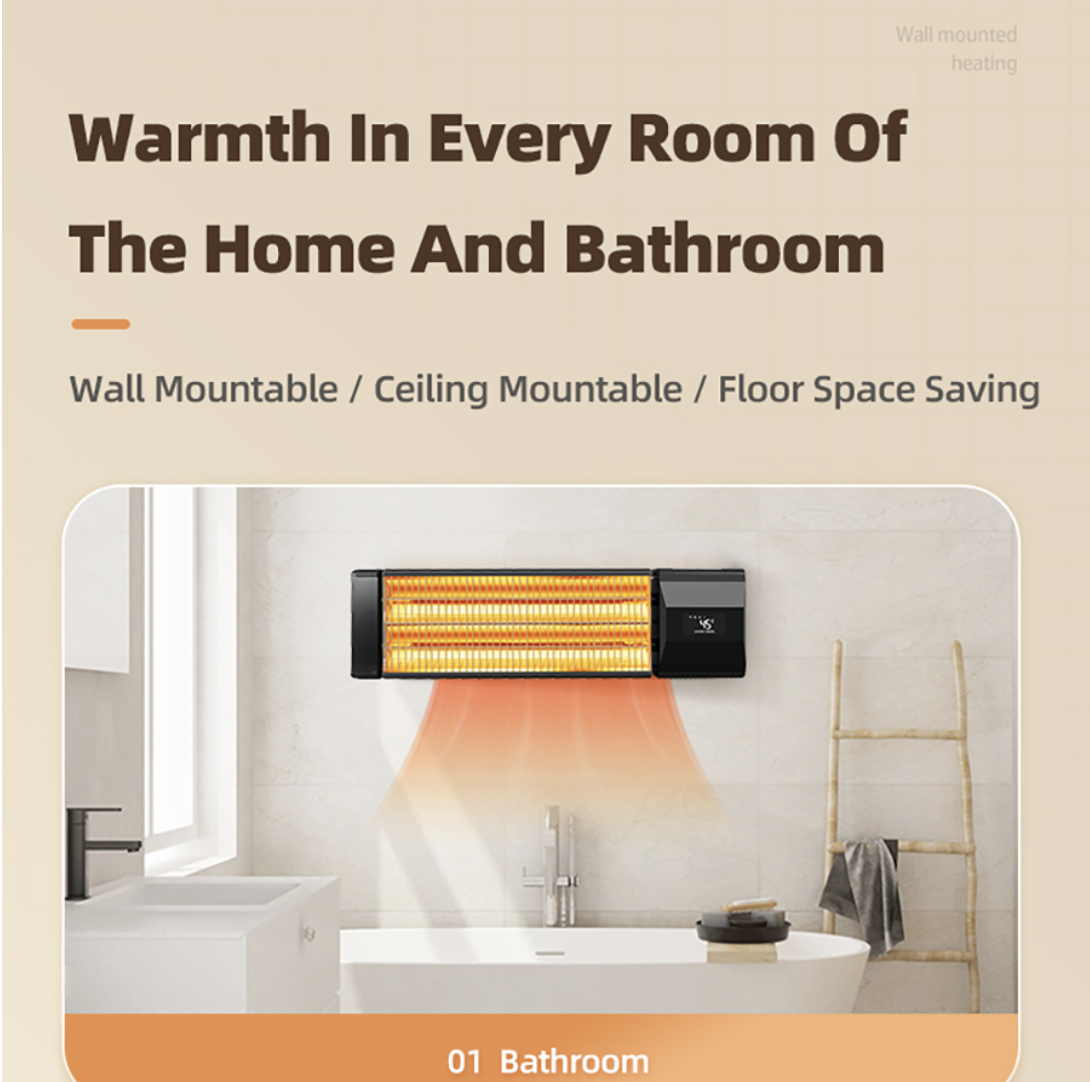

Aesthetics also play a role, especially for residential units, where the casing may include heat-resistant plastics or decorative finishes.

Component Fabrication: From Raw Material to Functional Parts

Heating Coil Winding

The NiCr wire is wound into a spiral or coil shape, allowing maximum surface area for heat generation.

Machines are used to ensure consistent winding, which is crucial for even heat output.

Ceramic and Mica Shaping

Mica sheets are cut and slotted to hold the coils in place while maintaining a safe electrical distance.

In PTC-based heaters, ceramic discs are molded and sintered under controlled conditions.

Casing and Frame Fabrication

Sheet metal is cut, stamped, and folded to create the heater’s structural framework.

Openings for controls, Lüftungsschlitze, and mountings are pre-cut to streamline the assembly process.

Assembly Line: Precision Meets Automation

Sub-Assembly Processes

Heating elements are inserted into their insulation brackets or housing compartments.

Internal wiring, such as connections to thermostats, sensors, and power cords, is completed with care.

Control Panel Installation

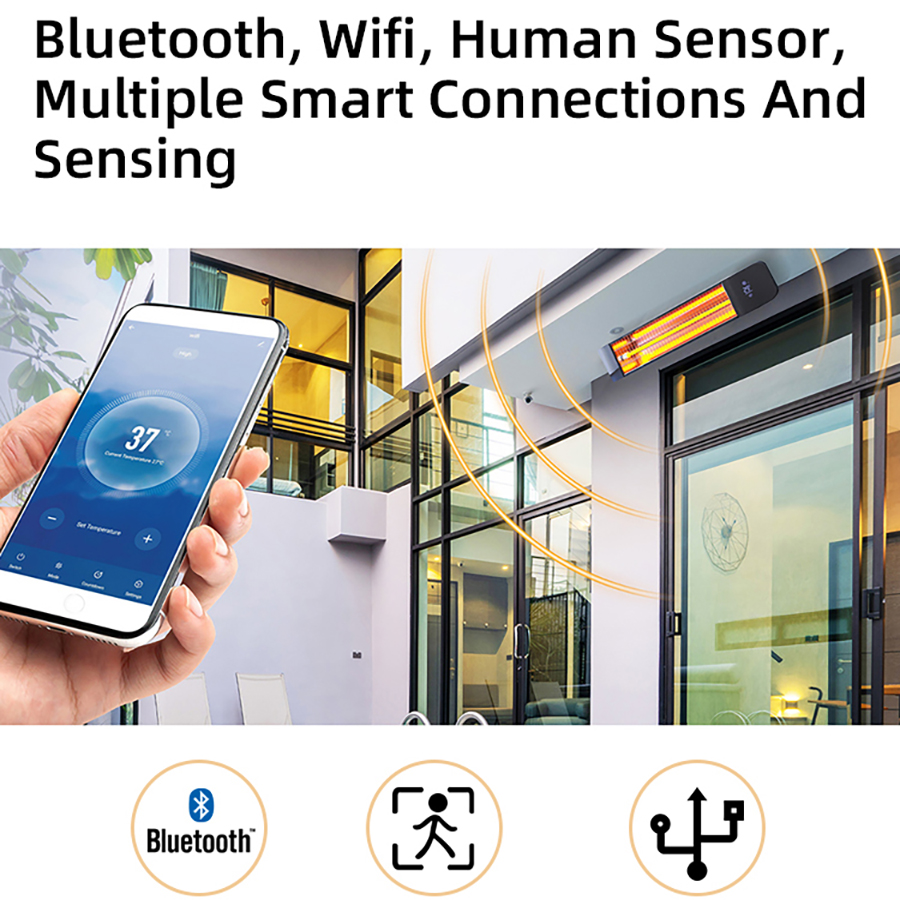

Digital or manual control boards are added, depending on the product’s design.

Safety features like overheat protection, Kippschalter, and auto shut-off timers are integrated during this stage.

Final Unit Assembly

All parts are secured within the outer casing using screws, clips, or welding.

Units are cleaned, labeled, and barcoded for traceability and inventory management.

Testing and Quality Control: Ensuring Safety and Performance

Electrical Safety Testing

Every unit is tested for leakage current, grounding resistance, and power consumption using standardized equipment.

Units must meet IEC or UL safety standards before they leave the factory.

Heating Efficiency Checks

Temperature sensors verify that the heater reaches the intended output temperature within a specific time.

Airflow and heat distribution are analyzed for even performance.

Durability and Stress Testing

Units undergo cycling tests to simulate years of use, turning them on and off repeatedly.

Environmental chambers expose products to extreme conditions to assess resistance to moisture, dust, and corrosion.

Packaging and Shipping: Final Touches Before Delivery

Secure, Eco-Friendly Packaging

Units are packed with foam inserts or molded pulp trays to prevent damage during transport.

Some manufacturers now opt for sustainable packaging materials to reduce environmental impact.

Labeling and Documentation

Packaging includes user manuals, warranty information, and safety warnings.

For exports, compliance documents and certifications are added for customs clearance.

Bulk Shipment Logistics

Products are palletized and loaded based on destination-specific packaging methods.

Factories may offer OEM/ODM packaging for private-label clients.

Maintenance Insight: How to Fix Electric Heater

Even the best-manufactured heaters need occasional maintenance. Here’s a quick guide on how to fix electric heater issues that often arise after purchase:

Common Troubleshooting Steps

- Heater not turning on

Check the power source, plug, and internal fuse.

- Uneven heating

May indicate a faulty thermostat or a partially burned-out heating element.

- Strange noises

Dust buildup or loose screws inside the casing can cause vibration or rattling sounds.

- Overheating or auto shut-off

Could be due to blocked vents or a failing temperature sensor.

Knowing these points helps buyers understand product design better and reduce post-sales service costs.

Air Cooler Manufacturer vs. Heater Manufacturer

If your business also sources seasonal climate products, you may work with both electric heater and Hersteller von Luftkühlern suppliers. Here’s how they differ:

Production Focus

- Air coolers require more plastic molding and water pump assembly, whereas heaters are metal- and coil-intensive.

- Testing protocols differ—air coolers are tested for humidity performance, while heaters undergo heat stress testing.

Manufacturing Lead Times

- Heater manufacturing is often more seasonal, requiring lead times before fall/winter.

- Air coolers peak in spring/summer, requiring a different production calendar.

Safety Compliance

- Electric heaters require stricter electrical safety certifications.

- Air coolers focus on water leakage prevention and fan motor efficiency.

Understanding the strengths of each factory can help you choose the right air cooler manufacturer or heater supplier depending on your product strategy.

Über Yika

Als vertrauenswürdiger Hersteller von Elektroheizungen, Yika holds certifications for ISO45001, ISO9001, und ISO14001. Zusätzlich, Yika wurde von Sedex als Supplier Plus-Mitglied anerkannt, Präsentation unserer robusten Lieferfähigkeiten.

Und Yika, unser R&D Das Team ist bestrebt, innovative und zuverlässige Heizlösungen zu liefern, um den vielfältigen Bedürfnissen unserer Kunden gerecht zu werden.

Abschluss

The manufacturing process of an electric heater is a fine-tuned balance of engineering, Effizienz, and safety—especially when compared to choosing between a gas heater or electric heater. Whether you’re sourcing from China or managing your own private label, understanding this process allows you to better evaluate supplier quality, pricing, and technical support.

Looking ahead, the demand for energy-efficient and smart heating solutions continues to grow. As technology evolves, and with trends shifting toward greener appliances, working with a skilled, transparent manufacturer can give your business a true competitive edge. Whether you’re exploring how heaters are made or learning how to fix electric heater units after market, this factory guide equips you with the insights you need.